Gear manufacturers tell you: gear types and characteristics

The gear manufacturer tells you:

Gears can be divided into three categories: cylindrical gears, bevel gears, worm and worm gears.

1. Types and characteristics of cylindrical gears

Spur gear

1) The axes of big and small gears are parallel to each other.

2) The direction line of the tooth length of the gear is parallel to the axis of the gear.

3) In external meshing transmission, the rotation direction of the two gears is opposite; in internal meshing transmission, the rotation direction of the two gears is the same.

4) Tooth shape can be made into normal teeth, short teeth, and can be displaced.

Helical cylindrical gear

1) The axes of big and small gears are parallel to each other.

2) In external meshing transmission, the two gears rotate in opposite directions; in internal meshing transmission, the two gears rotate in the same direction.

3) Tooth shape can be made into normal teeth, short teeth, and can be displaced.

4) An angle between the direction line of the tooth length and the axis of the gear

5) The meshing transmission is smoother than the spur gear transmission, and the transmission force is larger.

6) Trouble in manufacturing spur gears

Helical gear

1) The axes of big and small gears can be parallel, staggered and perpendicular to each other in space.

2) Big and pinion gears can rotate in the same direction or vice versa.

3) The suspected rotation angles of large and pinion gears can be equal or unequal.

4) When the spinning angle of pinion is large enough to a certain extent, it becomes a scorpion rod.

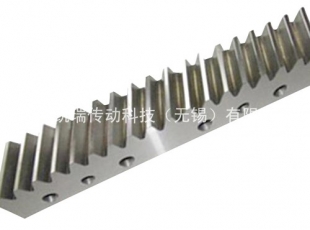

Gear and rack

1) The gear meshing with the rack, which can be spur or helical gear, has the characteristics of spur or helical gear.

2) The rack and gear drive is to turn rotation into linear movement or to turn movement into rotation.

3) The rack is formed when the diameter of the gear is infinite.

2. Types and characteristics of bevel gears

Spur bevel gear

1) The axes of big and small gears intersect at the apex of the cone.

2) When the bevel angle of the pitch of the big gear equals 90 degrees, it becomes a plane shaped gear; when the bevel angle is greater than 90 degrees, it becomes an internal meshing bevel gear.

Helical bevel gear

1) The tooth line is oblique, tangent to a circle, and does not intersect with the cone top.

2) The rotation angles of big and small gears are equal, but the direction is opposite.

3) Smoother transmission than straight bevel gears

Spiral bevel gear

1) Smooth transmission, large force transmission, suitable for off-speed transmission

2) The rotation angles of big and small gears are equal, but the direction is opposite.

3) The axes of the two gears intersect at the apex of the cone.

4) Spiral bevel gears are further divided into circular arc teeth, extended epicycloid teeth and quasi-involute teeth.

3. Types and characteristics of worm and worm wheel

Cylindrical Worm and Worm Wheel

Worm gear

1) The tooth shape on the axial section of worm is straight line.

2) Easy to manufacture

Linear worm

1) The tooth shape of the normal tangent of the worm and tadpole spiral is straight line.

2) Among the three kinds of worm, it is a better one, which is more common.

Involute worm

The tooth shape on the plane parallel to the worm axis and tangent to the base cylinder is linear.

Arc Worm and Worm Wheel

1) Efficiency, good oil film formation

2) High bearing capacity

3) Complex manufacturing and assembly

4) also known as spherical worm gear pair

5) Tooth type can be divided into original type and modified plough. The purpose of the modification is to facilitate the formation of oil film on worm and worm wheels in transmission.

Previous page:Design principle and stability of DSKR rack

The cutting-edge gear processing technology, brilliant fight!

Publication time:2019-10-09

Development Trend of Gear Processing Technology and Equipment

Publication time:2019-10-09

Some Key Points to Be Noticed in Gear Processing and Manufacturing

Publication time:2019-10-09

Why do we always want to do Gear processing, but we cant do it well?

Publication time:2019-10-09

Development Trend of Gear Processing Technology and Equipment

Publication time:2019-10-09

Introduction of Gear Processing

Publication time:2019-10-09

Common Defects and Solutions in Gear Hobbing

Publication time:2019-10-09

Several Key Technologies in Rack Grinding Machine

Publication time:2019-10-09

What is gear machining?

Publication time:2019-10-08

The Advantage of Rack Processing Roller Rack in Motion Mechanism

Publication time:2019-10-08

Introduction to the Characteristics and Parameters of Rack Machining Rack

Publication time:2019-10-08

Common Materials for Gear Processing

Publication time:2019-10-08

1The cutting-edge gear processing technology, brilliant fight!

2019-10-09

2Development Trend of Gear Processing Technology and Equipment

2019-10-09

3Some Key Points to Be Noticed in Gear Processing and Manufacturing

2019-10-09

4Why do we always want to do Gear processing, but we cant do it well?

2019-10-09

5Development Trend of Gear Processing Technology and Equipment

2019-10-09

6Introduction of Gear Processing

2019-10-09