Common Materials for Gear Processing

Common materials for gear processing:

Forged steel

According to the hardness of tooth surface, it can be divided into two categories.

When HB < 350, it is called soft tooth surface.

When HB > 350, it is called hard tooth surface.

1. Hardness of tooth surface HB<350

Process: forging blank normalizing rough turning conditioning and finishin

Common materials; 45, 35SiMn, 40Cr, 40CrNi, 40MnB

Characteristic:

It has good comprehensive performance, high strength and hardness of the face, and good toughness of the core.

After heat treatment, the cutting accuracy can reach 8 grades.

Simple manufacture, high economy, high productivity and low precision requirement

2. Hardness of tooth surface HB>350

When medium carbon steel is used:

Process: forging blank normalization rough cutting conditioning fine cutting high, medium frequency quenching low temperature tempering honing or abrasive running-in, electric spark running-in.

Common Materials: 45, 40Cr, 40CrNi

Characteristic:

High hardness HRC = 48-55, high contact strength and good wear resistance.

The tooth core maintains toughness after quenching and tempering, has good impact resistance and high bearing capacity.

Accuracy decreases by half, up to 7 levels of accuracy.

It is suitable for mass production, such as medium speed and medium load gearbox gears for automobiles and machine tools.

When using low carbon steel:

Forging blank normalization roughing tempering finishing carburizing and quenching low temperature tempering grinding teeth. Grades 6 and 7.

Common materials; 20Cr, 20CrMnTi, 20MnB, 20CrMnTo

Characteristic:

Hardness of tooth surface, strong bearing capacity.

Good core toughness and impact resistance

Suitable for high speed, heavy load, overload transmission or compact structure requirements occasions, locomotive main transmission gear, aviation gear.

Two. Cast steel

When the diameter of gear is d 400 mm, the structure is complex and the forging is difficult, cast steel can be used.

Material ZG45.ZG55, normalizing treatment. Normalization, tempering.

Three, cast iron

It has strong gluing and pitting resistance, but poor impact and wear resistance.

Suitable for stable operation, low power, large size and complex shape. It can work under the condition of oil shortage and suitable for open drive.

IV. Non-metallic Materials

Cloth, wood, plastic, nylon, suitable for high-speed light load.

When selecting materials, consideration should be given to:

Different working conditions and different failure modes of gear teeth are the basis for determining strength calculation criteria and selecting materials and heat treatment of gears.

1. When the gear teeth are easy to break under impact load, the material with better toughness should be chosen, and the low carbon steel can be used for carburizing and quenching.

2. For high-speed closed transmission, the tooth surface is easy to pit corrosion. Material with better hardness should be selected, and medium carbon steel surface quenching should be selected.

3. When the gear teeth are broken, pitting and wear can occur at low speed and medium load, mechanical strength and tooth surface hardness should be selected.

Material with good mechanical properties can be tempered and finely cut with medium carbon steel.

4. Make every effort to reduce the variety of materials, facilitate management, and consider resources and supply.

5. When the structure size is compact and the wear resistance is high, alloy steel should be used.

6. Equipment and technology of the manufacturing unit.

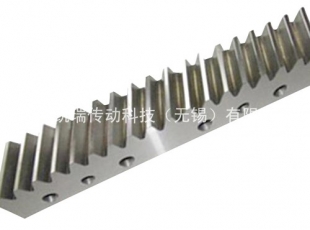

Previous page:Introduction to the Characteristics and Parameters of Rack Machining Rack

next page:没有了…

The cutting-edge gear processing technology, brilliant fight!

Publication time:2019-10-09

Development Trend of Gear Processing Technology and Equipment

Publication time:2019-10-09

Some Key Points to Be Noticed in Gear Processing and Manufacturing

Publication time:2019-10-09

Why do we always want to do Gear processing, but we cant do it well?

Publication time:2019-10-09

Development Trend of Gear Processing Technology and Equipment

Publication time:2019-10-09

Introduction of Gear Processing

Publication time:2019-10-09

Common Defects and Solutions in Gear Hobbing

Publication time:2019-10-09

Several Key Technologies in Rack Grinding Machine

Publication time:2019-10-09

What is gear machining?

Publication time:2019-10-08

The Advantage of Rack Processing Roller Rack in Motion Mechanism

Publication time:2019-10-08

Introduction to the Characteristics and Parameters of Rack Machining Rack

Publication time:2019-10-08

Common Materials for Gear Processing

Publication time:2019-10-08

1The cutting-edge gear processing technology, brilliant fight!

2019-10-09

2Development Trend of Gear Processing Technology and Equipment

2019-10-09

3Some Key Points to Be Noticed in Gear Processing and Manufacturing

2019-10-09

4Why do we always want to do Gear processing, but we cant do it well?

2019-10-09

5Development Trend of Gear Processing Technology and Equipment

2019-10-09

6Introduction of Gear Processing

2019-10-09