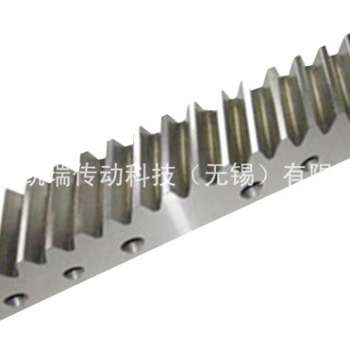

Rack manufacturer oblique rack

- Product Classification:Helical rack

- product labeling:manufacturer

- Number of visits:Already 2020Customer

Contact us:18626363628

Product introduction

Measures taken by rack manufacturers to maintain racks:

1. To make sure that the lubricant we use is the right rack oil in the rack, not all the lubricants are good for the rack, we should choose the right lubricant.

2. In order to avoid excessive accumulation of lubricants, only the key parts of the rack must be oiled. After oiling, the wear and abnormal sound of the rack can be reduced.

3. In other parts of the rack, only a little lubricant is needed to prevent rust.

4. When greasing the rack, it is impossible to do so perfectly, so wipe off excessive lubricant on the rack surface before finishing.

5. As far as transmission vehicles are concerned, attention should also be paid to rear transmission pulleys, gears and flywheels. Use the same principle to maintain and lubricate these parts.

6. After lubricating oil on rack, wipe excess oil on rack with dry cloth to avoid the adhesion of dirt and dust.

7. Every time the rack is cleaned, wiped or cleaned with solvent, it must be lubricated.

8. Before lubricating, make sure the rack is dry. Do not lubricate the rack after rain.

9. Infiltrate the lubricant into the rack bearing and wait for it to become viscous or dry.

1. To make sure that the lubricant we use is the right rack oil in the rack, not all the lubricants are good for the rack, we should choose the right lubricant.

2. In order to avoid excessive accumulation of lubricants, only the key parts of the rack must be oiled. After oiling, the wear and abnormal sound of the rack can be reduced.

3. In other parts of the rack, only a little lubricant is needed to prevent rust.

4. When greasing the rack, it is impossible to do so perfectly, so wipe off excessive lubricant on the rack surface before finishing.

5. As far as transmission vehicles are concerned, attention should also be paid to rear transmission pulleys, gears and flywheels. Use the same principle to maintain and lubricate these parts.

6. After lubricating oil on rack, wipe excess oil on rack with dry cloth to avoid the adhesion of dirt and dust.

7. Every time the rack is cleaned, wiped or cleaned with solvent, it must be lubricated.

8. Before lubricating, make sure the rack is dry. Do not lubricate the rack after rain.

9. Infiltrate the lubricant into the rack bearing and wait for it to become viscous or dry.

Previous page:Rack manufacturer oblique rack

next page:没有了…

Urban Distribution

Recommended products

Popular articles

Common Defects and Solutions in Gear Hobbing

Publication time:2019-10-09

Several Key Technologies in Rack Grinding Machine

Publication time:2019-10-09

Why do we always want to do Gear processing, but we cant do it well?

Publication time:2019-10-09

Development Trend of Gear Processing Technology and Equipment

Publication time:2019-10-09

popular articles

1The cutting-edge gear processing technology, brilliant fight!

2019-10-09

2Development Trend of Gear Processing Technology and Equipment

2019-10-09

3Some Key Points to Be Noticed in Gear Processing and Manufacturing

2019-10-09

4Why do we always want to do Gear processing, but we cant do it well?

2019-10-09

5Development Trend of Gear Processing Technology and Equipment

2019-10-09

6Introduction of Gear Processing

2019-10-09

7Common Defects and Solutions in Gear Hobbing

2019-10-09

8Several Key Technologies in Rack Grinding Machine

2019-10-09