The Advantage of Rack Processing Roller Rack in Motion Mechanism

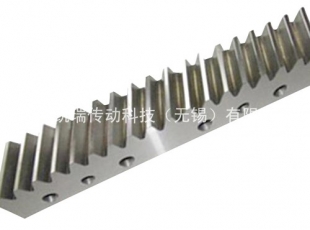

Rack processing:

The roller rack driving mechanism is a new type of linear driving mechanism. Compared with the traditional gear rack driving mode, the roller rack driving mode has more superior driving effect. The roller rack ensures zero backlash on both sides of the gear teeth, which can achieve high-speed operation ability. The reciprocating positioning accuracy will be more accurate than the traditional gear rack positioning accuracy. Roller rack drive in the automated production line also greatly improves the efficiency of production line reciprocating, so that the accuracy of equipment movement has been further improved, providing an important guarantee for the smooth progress of the next process.

Roller guides have unique advantages for applications requiring fast, smooth, and poor working conditions for linear guides.

(1) The transmission of roller guide rail has the basic characteristics of fast, smooth and low impetuosity.

(2) The structure forms of guideways and sliders are very diverse, which can meet the needs of wide application. The structure of guide rail includes: telescopic guide rail, linear guide rail, curve guide rail, circular guide rail, 360 degree circular arc guide rail, etc. The slider of the roller linear guide is no longer rigid to the traditional cuboid design, but can be creatively designed to any structure according to the customer's application needs, such as fixing the roller on a connecting plate as a slider.

(3) Rollers based on different types of bearings can meet the application requirements of different loads and torques. According to the requirements of axial and radial loads in specific applications, roller can choose roller based on ball bearing, tapered roller bearing or needle roller bearing. The rollers are divided into concentric rollers and eccentric rollers. Satisfactory preloading force can be obtained by simple adjustment, which makes the slider move smoothly, quickly and without clearance.

(4) Wider load-carrying range: It can meet the demand of load transmission from several kilograms to several tons. For heavy-duty applications, perfect solutions can be provided for applications requiring linear guides to withstand heavy loads and withstand "heavy-duty cycles".

(5) In harsh environment, dust and cutting chips have little effect on the roller guide. This means that roller guides have longer service life, lower maintenance and replacement costs, and higher customer satisfaction.

Previous page:What is gear machining?

next page:Introduction to the Characteristics and Parameters of Rack Machining Rack

The cutting-edge gear processing technology, brilliant fight!

Publication time:2019-10-09

Development Trend of Gear Processing Technology and Equipment

Publication time:2019-10-09

Some Key Points to Be Noticed in Gear Processing and Manufacturing

Publication time:2019-10-09

Why do we always want to do Gear processing, but we cant do it well?

Publication time:2019-10-09

Development Trend of Gear Processing Technology and Equipment

Publication time:2019-10-09

Introduction of Gear Processing

Publication time:2019-10-09

Common Defects and Solutions in Gear Hobbing

Publication time:2019-10-09

Several Key Technologies in Rack Grinding Machine

Publication time:2019-10-09

What is gear machining?

Publication time:2019-10-08

The Advantage of Rack Processing Roller Rack in Motion Mechanism

Publication time:2019-10-08

Introduction to the Characteristics and Parameters of Rack Machining Rack

Publication time:2019-10-08

Common Materials for Gear Processing

Publication time:2019-10-08

1The cutting-edge gear processing technology, brilliant fight!

2019-10-09

2Development Trend of Gear Processing Technology and Equipment

2019-10-09

3Some Key Points to Be Noticed in Gear Processing and Manufacturing

2019-10-09

4Why do we always want to do Gear processing, but we cant do it well?

2019-10-09

5Development Trend of Gear Processing Technology and Equipment

2019-10-09

6Introduction of Gear Processing

2019-10-09