Common Defects and Solutions in Gear Hobbing

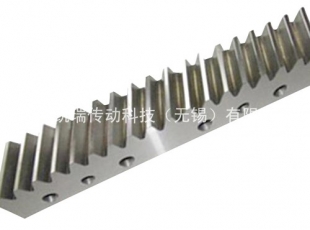

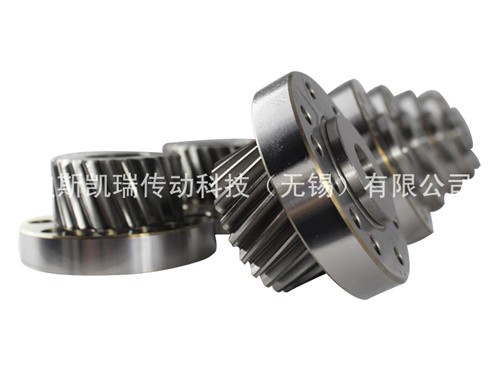

Gear is a common part in mechanical product design. Hobbing is the most widely used part in gear profile processing. It can process not only straight and helical cylindrical gears, but also worm gears and spline shafts. Hobbing is suitable for single piece small batch production and mass production. This article will introduce the processing principle of hobbing gear and the treatment of common defects.

Hobbing gear can be regarded as gear and rack transmission without meshing clearance. When the hobbing gear rotates for a week, it is equivalent to the rack moving a cutter tooth in the normal direction. Hobbing is the most widely used cutting method at present. It can process involute gears, circular arc gears, cycloid gears, sprockets, ratchets, worm gears and envelope worm, and its accuracy can generally reach DIN4-7 level. At present, the advanced hobbing technologies include multi-head hobbing, hard surface hobbing, large gear hobbing and high-speed hobbing.

Incorrect number of teeth

Main cause

1) incorrect adjustment of gear for gear-splitting exchange

2) Error in hob selection

3) The workpiece blank size is correct

4) Wjen hobbing helical gears, the additional motion direction is not right.

Resolvent

1) Re-adjust the gear of gear-splitting exchange and check whether the middle gear is correctly installed.

2) Rational selection of Hobs

3) Replacement of workpiece blanks

4) Increase or decrease the intermediate wheel in differential exchange gears

2. Abnormal Tooth Profile-Tooth Surface Arrowing

Main cause

There are four kinds of workpiece defects in hobbing cutter because of too big error of tooth profile or too much instantaneous speed ratio of inability to split teeth.

1) After the hob is grinded, the cutter teeth have poor equivalence.

2) Hob Axial Moving Forest

3) Large radial runout of hob

4) blunt hob

Resolvent

Main methods: Focus on the quality of hob grinding, hob installation accuracy and machine tool spindle geometric accuracy:

1) Controlling the grinding quality of Hobs

2) Guarantee the installation accuracy of hobs, while installing hobs, can not knock; gasket face is flat; nut face is vertical; cone hole should be clean; bracket installed, can not leave clearance.

3) Reviewing the rotational accuracy of machine tool spindle and repairing and adjusting hob spindle bearings, especially thrust gaskets

4) Replacement of new knives

3. Abnormal Tooth Profile-Asymmetric Tooth Profile

Main cause

1) incorrect hob installation

2) After hob grinding, the radial error of the front edge surface is large.

3) The helix angle or lead error is large after hob grinding.

4) The error of hob installation angle is too large

Resolvent

1) Setting knives with "gnawing knife and flower" method or knife gauge

2) Controlling the Grinding Quality of Hobs

3) Installation Solution of Re-adjusting Hob

4. Abnormal Tooth Shape-Incorrect Tooth Shape Angle

Main cause

1) Tooth angle error of hob itself is too larg

2) After hob grinding, the radial error of the front edge surface is large.

3) The error of hob installation angle is large.

Resolvent

1) The Accuracy of Rational Selection of Hobs

2) Controlling the Grinding Quality of Hobs

3) Re-adjust the installation angle of hob

5 Tooth Profile Abnormality-Periodic Error of Tooth Profile

Main cause

1) After hob installation, the radial or axial movement is large.

2) Non-uniform rotation of machine tool table

3) Eccentricity or bumping of tooth surface in installation of cross-wheel or gear-splitting exchange

4) Sliding board of tool holder is loose

5) The unreasonable clamping of workpiece causes oscillation

Resolvent

1) Control the installation accuracy of Hobs

2) Check the axial movement of indexing worm of machine tool table and adjust and repair it.

3) Inspection of the installation and operation of the spanning and gear-splitting exchange gears

4) Plug iron for adjusting tool holder slide

5) Correct scheme of reasonable selection of workpiece clamping

6 Tooth Ring Radial Runout Excess

Main cause

The center of workpiece inner hole does not coincide with the revolving center of machine tool table

Regarding machine tools and fixtures:

Large radial runout of worktable

Spindle wear or radial runout

Deviation or loosening of top and bottom thimbles

The fixture positioning end face is not perpendicular to the revolving center line of the worktable

Work clamping components, such as washers and caps, are not accurate enough

Relevant aspects of work:

Diameter Excess of Workpiece Positioning Hole

our-alignment of coaxiality between the outer circle and the inner hole when the outer circle of the aligning workpiece is installed

Workpiece clamping rigidity difference

Resolvent

Focusing on the Rotary Accuracy of the Controller Setting Workbench and the Correct Installation of the Workpiece

Regarding machine tools and fixtures:

Inspection and repair of rotary guide of worktable

Reasonable Use and Maintenance of Workpiece Spindle

Accuracy of Repairing Posterior Column and Top Needle

The fixture positioning end is not perpendicular to the revolving center line of the worktable

Improving the accuracy of workpiece clamping components, such as washers and caps

With regard to workpieces:

Controlling the Dimensional Accuracy of Workpiece Positioning Hole

Controlling Coaxiality Error of Outer Circle and Inner Hole of Workpiece

The main reason why clamping force should be applied to parts with enough rigidity

7 Tooth Direction Error Excess

Main cause

The hob's vertical feed direction deviates too much from the axis direction of the inner hole of the billet. When processing helical gears, there is also incorrect additional motion.

Regarding machine tools and fixtures:

The unequal axes between the triangular guide of the column and the worktable

The end face of the worktable fluctuates greatly

Upper and lower apex with different axes

Large meshing clearance of indexing worm gear pair

There are periodic errors in the transmission of indexing worm gears

Vertical feed screw pitch error is large

Great Error of Gear Splitting and Differential Exchange

Relevant aspects of work:

The two ends of the billet are not parallel

Workpiece positioning hole is not perpendicular to end face

Resolvent

The aim is to control the geometric accuracy of machine tools and correct installation of workpieces.

Regarding machine tools and fixtures:

Repair the accuracy of column and control the thermal variant of machine tool

Revolving accuracy of repairing worktable

Accuracy of restoring posterior posts or top and bottom thimbles

Reasonable adjustment of meshing clearance of indexing worm gear pair

Repairing the parts accuracy of indexing worm gear pair

Vertical feed screw should be replaced in time when its accuracy can not be reached due to wear and tear.

Calculating error of differential exchange gear should be controlled

Workpiece-related aspects

Controlling Parallelism Error of Two End Faces of Blank

Controlling the Verticality of the Positioning Hole and the End Face of the Blank

Over-tolerance of accumulated error correlation of 8 teeth spacing

Main cause

The maximum error of the uneven rotation of the hobbing table is too large:

One span of transmission accuracy of indexing worm gear pair

Radial runout and large end runout of worktable

Too loose meshing or bumping phenomena of gear-splitting exchange wheels

Resolvent

Focusing on the accuracy of the gear-splitting kinematic chain, especially the indexing worm gear pair and hob.

Repairing transmission accuracy of indexing worm gear pair

Revolving accuracy of repairing worktable

Check the gear and meshing tightness and running condition

9 Tooth Surface Defect-Tea

Main cause

Inhomogeneous Material of Tooth Blank

Improper heat treatment of tooth blank

Incorrect selection of cutting parameters results in chip tumors

Low efficiency of cutting fluid

The hob is blunt and not sharp

Resolvent

Controlling the Material Quality of Tooth Blanks

Correct selection of heat treatment methods, especially hardness after quenching and tempering, suggests normalizing treatment.

Correct selection of cutting parameters to avoid chip tumors

Choosing cutting fluid correctly, especially paying attention to its lubrication performance

Replacement of a new knife

10 Tooth Surface Defect-Grinding Tooth

Main cause

The abrupt change of the position between the hob and the billet results in:

Too loose triangular guide of pillar causes sudden change of hob feed, too tight triangular guide of pillar causes creeping phenomenon.

Large meshing clearance of helical gears in tool holder

Oil pressure instability

Resolvent

Adjustment of Triangular Guideway of Column: Requirement of Tightness and Appropriateness

The tool holder should be replaced if it is worn out due to long service time.

Resonable maintenance of machine tools, especially cleanliness, to keep the oil circuit unblocked: oil pressure remains stable

11 Tooth Surface Defect-Vibration Mark

Main cause

Vibration causes:

Large clearance in a transmission link of machine tool

Insufficient clamping rigidity of workpiece and hob

Selection of cutting parameters is too large

Large clearance after rear bracket installation

Resolvent

Finding and eliminating vibration sources:

Timely overhaul of machine tools with long service time and serious wear and tear

Increasing the clamping rigidity of hobs, such as reducing the distance between supports: Hobs with shanks should be selected as large as possible. Increase the clamping rigidity of workpiece: for example, maximize the supporting end face, the supporting end face (including workpiece) only quasi-concave: shorten the distance between top and bottom pins

Correct selection of cutting parameters

Correct installation of rear bracket

12 Tooth Surface Defect-Fish Scale

Main cause

Imroper heat treatment of billet, in which steel parts after quenching and tempering treatment are more common

Resolvent

Control hardness of conditioning treatment as appropriate

It is suggested that normalizing should be used as the preheating point of the billet.

Previous page:Introduction of Gear Processing

The cutting-edge gear processing technology, brilliant fight!

Publication time:2019-10-09

Development Trend of Gear Processing Technology and Equipment

Publication time:2019-10-09

Some Key Points to Be Noticed in Gear Processing and Manufacturing

Publication time:2019-10-09

Why do we always want to do Gear processing, but we cant do it well?

Publication time:2019-10-09

Development Trend of Gear Processing Technology and Equipment

Publication time:2019-10-09

Introduction of Gear Processing

Publication time:2019-10-09

Common Defects and Solutions in Gear Hobbing

Publication time:2019-10-09

Several Key Technologies in Rack Grinding Machine

Publication time:2019-10-09

What is gear machining?

Publication time:2019-10-08

The Advantage of Rack Processing Roller Rack in Motion Mechanism

Publication time:2019-10-08

Introduction to the Characteristics and Parameters of Rack Machining Rack

Publication time:2019-10-08

Common Materials for Gear Processing

Publication time:2019-10-08

1The cutting-edge gear processing technology, brilliant fight!

2019-10-09

2Development Trend of Gear Processing Technology and Equipment

2019-10-09

3Some Key Points to Be Noticed in Gear Processing and Manufacturing

2019-10-09

4Why do we always want to do Gear processing, but we cant do it well?

2019-10-09

5Development Trend of Gear Processing Technology and Equipment

2019-10-09

6Introduction of Gear Processing

2019-10-09