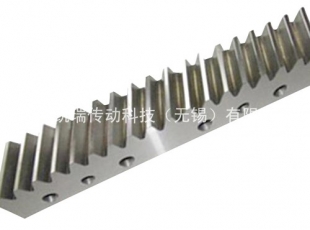

Deformation Method for Preventing DSKR Rack from Heat Treatment

When the requirement of rack precision is higher and higher in some application fields, the rack manufactured by rack shaper or rack milling machine can not meet the requirement. High-precision rack grinder has become a necessary product in the market. Today, let's have a brief understanding of the high-end technology of rack grinders.

1. Effective Technology

1) Because of the particularity of DSKR rack, grinding wheels are generally wider, grinding multiple alveols at a time. At this time, grinding load is larger, and the rigidity of the machine tool is good enough, and the power of the spindle is large enough.

2) The working table is wide enough to clamp and process multiple racks at one time, which also requires the machine tool to have enough rigidity.

3) The use of single small rounded diamond roller can meet the requirements of any modulus, any tooth surface (chamfer, non-standard rack, etc.) rack grinding wheel auto-dressing, which greatly reduces the user's use cost and operation difficulty.

2, AE Technology

AE technology is actually an application of acoustic emission sensor. AE technology can realize automatic alignment of workpiece, automatic machining margin detection and processing margin allocation, etc. In addition, AE is also an important technical means to prevent collision.

3. Dynamic Balance Technology

Dynamic balance is a common technology for all grinding machine tools. The poor dynamic balance of grinding wheel spindle will directly affect the grinding accuracy of workpiece, resulting in large vibration and poor grinding accuracy.

4. On-line Detection Technology

Through on-line testing, the test report can be output quickly, and compensation processing can be carried out according to the test results, which greatly shortens the process of processing - three coordinates testing - adjusting machine tools - reprocessing.

5. Intelligent Process Software

Machine tool operators are concerned about the ease of use of machine tools. Gear grinders must have intuitive and easy-to-operate human-machine interface, intelligent error prevention mechanism and intelligent process operation.

Previous page:Precision gear rack transmission calculation and basic knowledge!

next page:没有了…

The cutting-edge gear processing technology, brilliant fight!

Publication time:2019-10-09

Development Trend of Gear Processing Technology and Equipment

Publication time:2019-10-09

Some Key Points to Be Noticed in Gear Processing and Manufacturing

Publication time:2019-10-09

Why do we always want to do Gear processing, but we cant do it well?

Publication time:2019-10-09

Development Trend of Gear Processing Technology and Equipment

Publication time:2019-10-09

Introduction of Gear Processing

Publication time:2019-10-09

Common Defects and Solutions in Gear Hobbing

Publication time:2019-10-09

Several Key Technologies in Rack Grinding Machine

Publication time:2019-10-09

What is gear machining?

Publication time:2019-10-08

The Advantage of Rack Processing Roller Rack in Motion Mechanism

Publication time:2019-10-08

Introduction to the Characteristics and Parameters of Rack Machining Rack

Publication time:2019-10-08

Common Materials for Gear Processing

Publication time:2019-10-08

1The cutting-edge gear processing technology, brilliant fight!

2019-10-09

2Development Trend of Gear Processing Technology and Equipment

2019-10-09

3Some Key Points to Be Noticed in Gear Processing and Manufacturing

2019-10-09

4Why do we always want to do Gear processing, but we cant do it well?

2019-10-09

5Development Trend of Gear Processing Technology and Equipment

2019-10-09

6Introduction of Gear Processing

2019-10-09